Leveraging Data and Telematics for Smarter Supply Chain and Forklift Automation

In today’s fast-paced business environment, the importance of data is undeniable. From identifying opportunities to boost efficiency and productivity to enhancing safety, data is transforming industries and shaping our daily lives.

Yet, for many supply chain and forklift fleet managers, the abundance of available data can be overwhelming. With so much information to process, it can be challenging to determine which data is most critical and how to use it to achieve business objectives. As the Internet of Things (IoT) continues to connect supply chains, new streams of data are constantly being uncovered and analyzed.

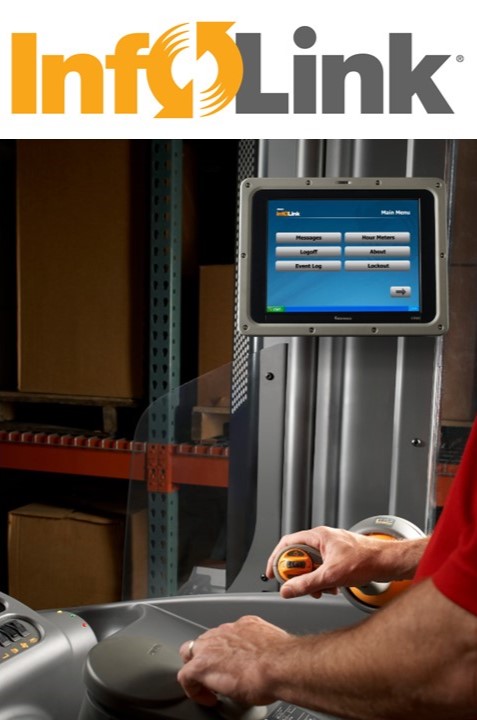

Fortunately, advancements in technology have made it easier to collect and focus on the data that matters. Tools like Crown’s InfoLink® operator and fleet management system are designed to simplify this process. By leveraging telematics, these systems provide actionable insights into the performance and utilization of equipment, operators, and processes, helping businesses achieve their goals with greater precision.

Turning Data Into Actionable Insights

The key to harnessing data effectively lies in aligning it with your organization’s business priorities. Setting clear objectives and identifying the specific data points needed to meet them is crucial for transforming raw data into actionable insights.

Telematics plays an essential role in this process. By integrating telematics systems like Crown’s InfoLink, companies can track and analyze data that supports their operational strategies. This capability is particularly valuable when implementing forklift automation, as it enables businesses to evaluate performance and ensure a seamless transition.

Telematics and Forklift Automation: A Powerful Combination

Forklift automation doesn’t eliminate the need for robust data management—on the contrary, telematics systems are critical for planning, executing, and optimizing automation strategies. Traditionally, telematics systems have focused on providing insights into operator and equipment performance. However, their integration with warehouse management systems (WMS) can deliver a more comprehensive view of warehouse operations, especially as fleets adopt more automated and semi-automated vehicles.

One innovative approach to forklift automation involves dual-mode technology, which allows forklifts to operate in both manual and automated modes. This flexibility accommodates dynamic production plans, ensuring adaptability in a constantly changing environment.

For instance, Crown’s DualMode R reach truck and DualMode T tow tractor are equipped to handle travel between fixed points autonomously. If an obstacle, like a misplaced pallet, blocks the path, a trained operator can switch the forklift to manual mode, navigate around the obstacle, and then return to automated mode. This seamless transition helps maintain workflow continuity and minimizes disruptions.

Unlocking the Full Potential of Automation with Telematics

To maximize the benefits of automation, telematics systems must track when forklifts switch between manual and automated modes. This data provides valuable insights into issues like unexpected delays or inefficiencies on high manual-traffic days.

Telematics systems also enhance accessibility to vehicle alerts and location data, often streamlining operations more effectively than traditional traffic managers. For example, when a forklift encounters a blockage in automated mode, the telematics system can send an alert with the location and reason for the stoppage, enabling quick resolution.

Building a Cohesive Strategy for Success

Individually, automation and telematics systems offer significant benefits. Together, they create a powerful synergy, combining data from various sources to provide a holistic view of warehouse operations. This unified approach helps businesses achieve their equipment utilization and automation goals, driving efficiency and delivering tangible results.

As supply chains continue to evolve, leveraging the right tools and strategies is essential for staying competitive. By integrating telematics and automation, businesses can turn data into a strategic asset, enhancing operations and unlocking new opportunities for growth.