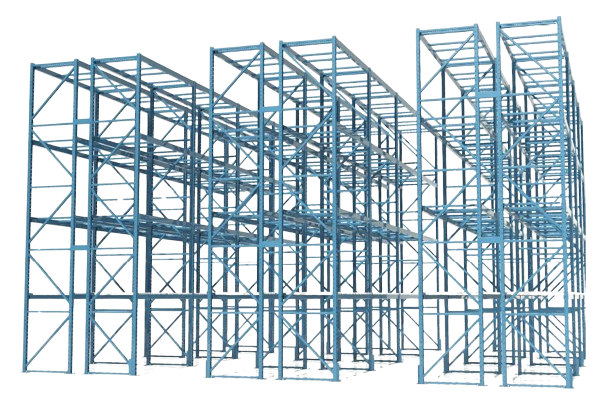

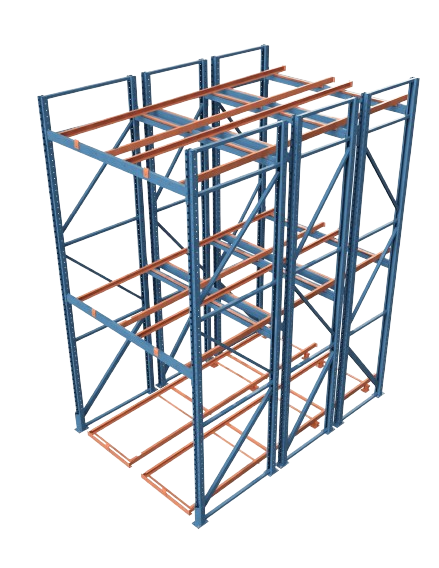

PALLET RACKING & SHELVING.

MADE IN CANADA.

Explore

PALLET RACKING AND SHELVINGCanadian-made Warehouse Racks and Shelves

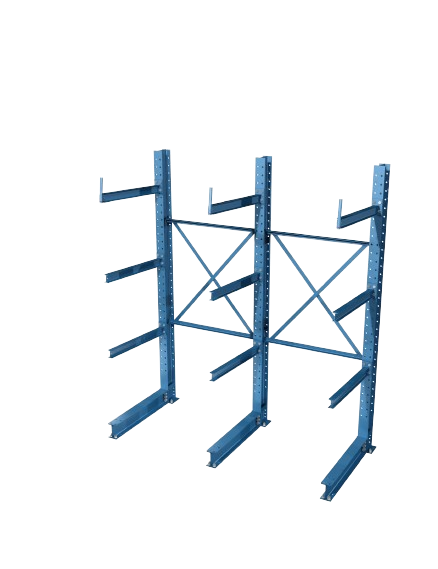

We specialize in delivering the perfect racking and shelving solutions for your warehouse. Our consultative approach ensures that your setup is not just efficient but tailored to your unique needs.

From initial consultation to installation, we handle every aspect of your racking, shelving, and equipment requirements. Our commitment to safety means that all our work meets the highest safety specifications and regulatory requirements, leaving your warehouse ready for peak performance.

What to consider when buying pallet racking and shelving.

Pallet racking and shelving are an integral piece of your warehouse system. Before making a decision, here are some considerations to take into account.

Your Trusted PartnerPallet Racking and Shelving.

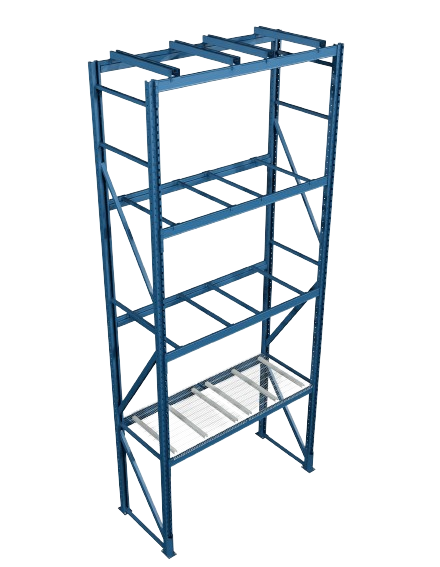

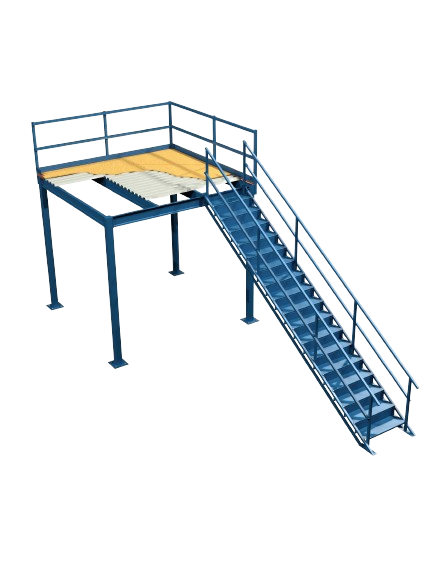

From boltless shelving to Very Narrow Aisle pallet racking, we offer the foundation to set up your warehouse.

Pallet Racking and Shelving Services

Proper warehouse alignment is essential to productivity, so let us get you set up with the right racking and warehouse solutions for your warehouse.

Our expert team of storage system designers and engineers is dedicated to optimizing your warehouse layout for enhanced storage capacity while adhering to current municipal bylaws and ensuring operational safety.

Our collaborative approach involves close coordination between our design and sales teams, ensuring that your customized layout aligns seamlessly with your unique Needs Assessment. Our layout drawings encompass comprehensive plan and elevation views, along with capacity and seismic load considerations.

For peace of mind, our inventoried storage products are engineered to meet standard safety workloads. Additionally, our engineering expertise extends to handling permit and seismic requirements, ensuring full compliance with local building authority regulations. Trust us to deliver tailored layouts that not only maximize efficiency but also prioritize safety and regulatory compliance.

As your material handling and equipment partner, we work to meet your objectives, such as:

- Storage capacity

- Flexibility to expand or contract

- Space utilization

- Increased productivity

- Pick vs. pallet location requirements

- Number of pallet movements

- Warehouse processing areas (staging, marshalling, etc)

Starting with a review of your specific material handling requirements and objectives, we will complete our Customer Needs Assessment with a survey of the existing or proposed inventories, building characteristics, and equipment. To do this assessment, we must gather information about:

- Building and site characteristics

- Ceiling height

- Dock door placement

- Slab capacity

- Soil conditions

- Material flow: receiving, storing, selection, transport and shipping

- Material handling equipment (typically forklifts) used to handle products

- Storage objectives

- Productivity objectives

- Safety considerations

- Products to be stored

Using the analysis, we will form an all-inclusive plan to help you meet your objectives. This plan will include prepared layout and design for a storage system and/or a specification for required equipment.

Ensure precision from the start. Proper installation is paramount for the optimal performance of your pallet racking and shelving products. At Arpac, we prioritize getting it right the first time.

Our dedicated onsite installation crews are committed to the correct installation of all systems, adhering to the specifications determined during the earlier engineering and layout phases. While self-installation is an option, we strongly recommend assigning larger and more intricate projects to our experienced installers for a seamless and worry-free experience.

Our on-site inspections, led by experts, identify safety measures and provide a detailed report highlighting concerns. Clients can choose and implement tailored solutions for their company. Committed to safety standards, our inspection services promptly address any issues, ensuring compliance with industry regulations. Trust our experts to guide you, prioritizing the secure management of your facility.

Pallet rack damage can result from various factors:

- Environmental Factors: Seismic activity, extreme weather events, or flooding can exert forces beyond design limits, causing deformation or collapse.

- Forklift Collisions: Accidents or collisions during pallet loading can occur due to operator errors, lack of training, or insufficient clearance between forklifts and racks.

- Inadequate Maintenance: Neglecting regular inspections and maintenance allows wear and tear, like rust or loose bolts, weakening the rack’s integrity.

- Improper Installation: Incorrect assembly, improper anchoring, or using incompatible components compromises stability, increasing the risk of damage.

- Lack of Training and Safety Procedures: Insufficient training, safety protocol adherence, or negligence during loading and unloading heighten the risk of accidents and rack damage.

- Overloading: Exceeding weight capacity can lead to structural damage, causing beams to bend, uprights to deform, or connections to fail.

- Improper Loading: Incorrectly positioning or unevenly placing pallets strains the rack structure, risking unbalanced weight distribution and potential failure.

HOW WE DO THINGS DIFFERENTLYA customized solution for each unique need and situation.

At ARPAC, You’re Our Partner. Your success is our success. We’re here to tackle your challenges together. Our product and application experts take the time to understand your unique needs, ensuring we provide the perfect tailored solution for your warehouse operations. We’re committed to delivering the right engineered solution the first time, with no surprises.

As a solutions-based provider, we focus on the seamless integration of every piece of your system. Expect boutique designs and innovative ideas that match your warehouse equipment requirements.